Description

Here are some of its advantages over 9th generation 12 volt battery kill switch:

- It is assembled in America and delivers through first-class mail.

- It has advanced internal programming for maximum efficiency with automotive stators. (PEP)

- Its new case was introduced last April 2019 specifically designed for automotive application.

- It has a superior cable construction with a 100% waterproof shrink tube.

- It offers extra flex cables for easy routing.

- It assures correct cable ends to custom fit isolator studs.

- The new smart 12v isolator switch can be left suspended in-line, as long as it is mounted with provided 3M Dual Lock™, or hard mounted with any provided screws.

- It is compatible with all battery types like dry cell, flooded lead-acid, AGM, and any hybrid types available.

- Compatible with the TRUE latest dual battery voltage meter (single meter dual display)

With its upgraded features, the TRUE Smart 12v isolator switch is specifically designed and programmed for automotive and marine applications, plus it is now 100% American-made. This new voltage-sensitive relay kit does not only provide the same application but also showcases the enhanced performance and a longer lifespan of up to 3 years.

A TRUE exclusive!

‘

‘

An important note from the designer:

“The TRUE 12v battery isolator switch is the 9th generation I have designed. The first-generation products which I have designed before I figured the proper programming include the QUAD BOSS/AOPEC/Keyline units.

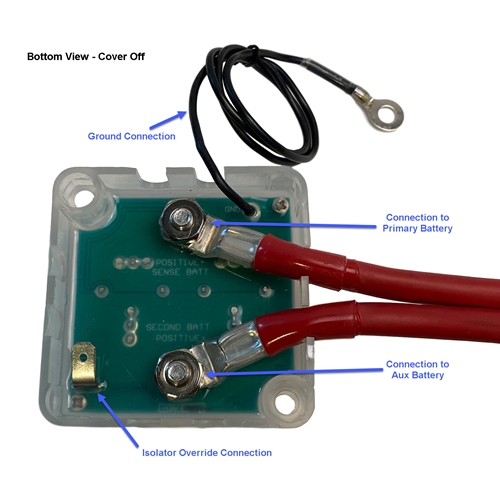

Together with PEP (Propriety Efficiency Programming), the all-new TRUE isolator kits have added lots of upgrades which includes the case design, circuit board design, and the type of cables that should be used in order to avoid insulation and terminal failures from possible corrosion.

Overall, its main goal is to provide stable and easy installation. The construction of the actual 12v dual battery isolator case has been exclusively redesigned for automotive application which then allows a hassle-free and versatile installation. There are possible cable access slots that need to be “knocked out” because it may cause a breach in the seal protecting the circuit board, which is why the front mounted studs are there to eliminate unnecessary holes.

Now, we made sure to move all our production processes as possible to America. These improvements made huge impacts that are essential for the benefit of all because we only aim to provide the best and most efficient products that fit the standards and demands of a vehicle’s owner.”

Dennis M. Hogan, Ph.D.

True Amalgamated, Inc.

Tags: GMC, GM